Configuration of Material Master in SAP MM

- Mohnish Baviskar

- Aug 24, 2023

- 3 min read

Updated: Sep 28, 2024

The Configuration of Material Master in SAP is a pivotal step in fine-tuning an enterprise's ERP system to manage materials effectively. This process involves defining attributes like material types, groups, and classes, as well as specifying crucial data points for accurate categorization and streamlined operations. Proper Material Master configuration establishes a robust foundation for inventory, procurement, and production planning, aligning the ERP system with the organization's unique needs and operational goals.

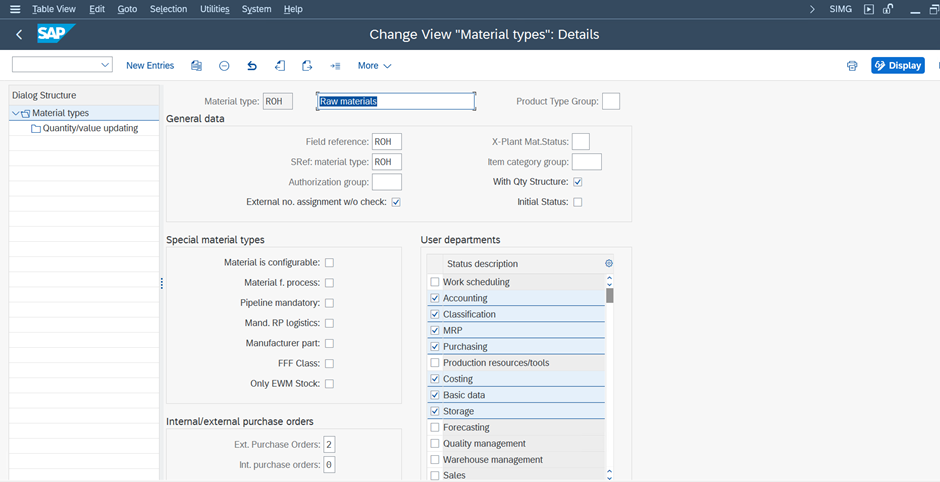

Material Type

Attribute that subdivides materials with the same properties into groups.

Path to create the material type

IMG ⇒ Logistics General ⇒ Material Master ⇒ Basic Settings ⇒ Material Types ⇒ Define Attributes of Material Types

T.Code: OMS2

STEP 1: On the Display IMG screen, select Define Attributes of Material Types, by following the above path.

STEP 2: Click the New Entries button or you can copy from the existing material type.

STEP 3: Fill in the required information such as the name of the material type and description. Click on Save. A new material type will be created.

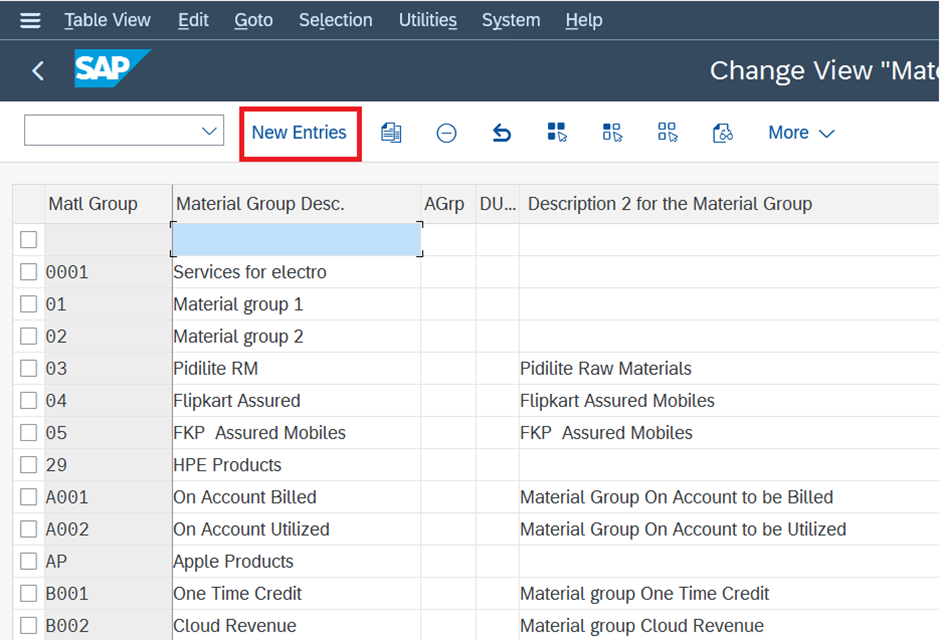

Material Group

Key that you use to group several materials or services with the same attributes, and to assign them to a particular material group.

Path to Create Material Group

IMG ⇒ Logistic General ⇒ Material Master ⇒ Settings for Key Fields ⇒ Define Material Groups

T.Code: OMSF

STEP 1: On Display IMG screen, select Define Material Groups, by following the above path.

STEP 2: Click the New Entries button.

STEP 3: Enter the name of the material group along with its description. Click the Save button. A new material group will be created.

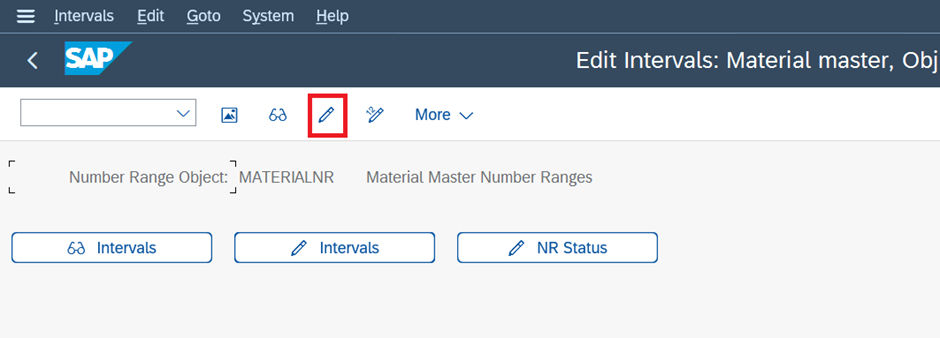

Number Ranges

When we construct a material master record, we identify each material by a unique number known as the material number. There are two methods for assigning a number to a material.

External Number Assignment- When constructing a material, you must supply your unique number (including alphabets or digits).

Internal Number Assignment- You do not need to specify any numbers when building a material. The system assigns a unique number to the material automatically.

Path to Create Number Range

IMG ⇒ Logistic General ⇒ Material Master ⇒ Basic Settings ⇒ Material Types ⇒ Define Number Range for Each material Type

T.Code: MMNR

STEP 1: On the Display IMG screen, select Define Number Range for Each Material Type, by following the above path.

STEP 2: Click the Intervals button.

STEP 3: We can define a number range here and EXT (external tab, if it is checked, then an external number can be assigned in that material). Click the Save button. The number Range is now defined for the material.

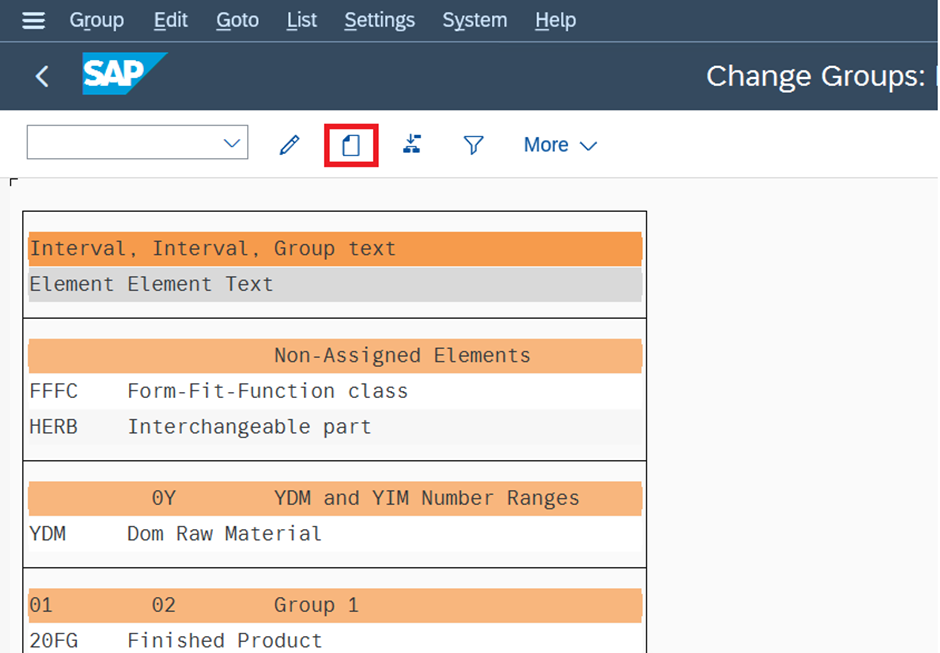

Assignment of Number Range

After we define it, we must assign it to a material group. To assign a number range, follow the procedures outlined below.

STEP 1: On the same screen, select the Groups tab.

STEP 2: Create a group to create new number ranges and assign them to the elements.

STEP 3: Enter the group name and create a new number range and Click on the save button.

STEP 4: Select the related material type and click on the assign element.

STEP 5: Select the number range and its complete.

These are the steps that should be followed to configure SAP system for creating Material.

This data will include information on the materials that a company can procure, produce, store, or sell.

For more details visit the link below:

#SAP #SAPConfiguration #MaterialMaster #SAPMM #SAPLogistics #SupplyChainManagement #ERP #SAPConsulting #InventoryManagement #Procurement #SAPImplementation #SAPModules #SAPTraining #SAPCommunity #BusinessProcess #DataManagement #SAPExpert #MasterData #SAPProjects #MaterialManagement #SAPCustomization #SAPConfig #Warehousing #SAPIntegration #SAPSupport #LogisticsManagement #SAPTechnology #SAPSystem #SupplyChainOptimization #SAPConsultant #InventoryControl #ProductionPlanning #SAPBestPractices #SAPWorkflow #SAPBusinessOne #ProcureToPay #SAPAutomation #VendorManagement #SAPAnalytics #SAPProcess #DemandPlanning #SAPSolution #SAPSkills #MaterialGroup #SAPBusinessProcesses #SAPTrainingAndCertification #SAPSuccessFactors #SupplyChainSolutions #SAPConfigurationTips #SAPMasterData #InventoryOptimization #SAPLogisticsManagement #SAPSupplyChain #SAPCustomization #SAPProjectManagement #WarehouseManagement

The function known as "WallTap" is the secret largest one to drift hunters earn great gaming prizes.Few individuals are aware of this capability.

EPTU Machine ETPU Moulding…

EPTU Machine ETPU Moulding…

EPTU Machine ETPU Moulding…

EPTU Machine ETPU Moulding…

EPTU Machine ETPU Moulding…

EPS Machine EPS Block…

EPS Machine EPS Block…

EPS Machine EPS Block…

AEON MINING AEON MINING

AEON MINING AEON MINING

KSD Miner KSD Miner

KSD Miner KSD Miner

BCH Miner BCH Miner

BCH Miner BCH Miner

I discovered that configuring Material Master in SAP MM was critical for good inventory management. It streamlines procedures and maintains data accuracy. If you need support with this topic, I propose finding online assignment help in Germany. Many professionals may provide insights and extensive explanations, helping you understand the nuances of SAP MM and improving your learning experience.